Shin-Etsu Sepla Film® is a Super Engineering Plastic Films; ultra thin and non-stretched.

- non-stretched film of non-crystallized plastics

- non-stretched and low crystallized film of crystallized plastics

- several surface patterns

PEEK (Polyether Ether Ketone) offers outstanding physical, thermal and chemical properties resulting in excellent resistance against thermal, chemical and mechanical stress and wear.

Shin-Etsu Polymer’s knowledge in micromoulding is used to create low internal tension ultrathin films starting from 3 μm of thickness.

Features:

- Ultra thin film created by non-stretching micro moulding in low crystallizing state

- High tensile strength and rigidity

- Superior heat tolerance

- Superior friction resistance

- Superior chemical resistance

- Roughening of film surface optional

- Sliding and conductivity characteristics optional (composite blending)

Applications for Sepla Film®:

- Acoustic membrane for speakers for small handheld devices

- Isolation layers in multilayer PCB or antenna for high frequency devices like 5G network terminals or network devices

- Isolation of wires for EV motors or wires in harsh environment applications

- Interior panels for airplanes

Shin-Etsu Sepla Film® - extended material property comparison

| Unit | PA9T | PEEK | Test method | ||

|---|---|---|---|---|---|

| Crystalline/Amorphous | - | Crystalline | Crystalline | ||

| Specific gravity | - | 1.14 | 1.31 | ||

| Glass transition point Melting point | °C | 125 300 | 146 339 | DSC ΔT: 10°C/min. |

|

| Linear expansion coefficient | MD* TD* | °C-1 | 31 • 10^-6 101 • 10^-6 | JIS K7197 ΔT: 5°C/min. |

|

| Elasticity or Tensile Modulus | MD* TD* | N/mm2 | 2168 2183 | 3720 2940 | JIS K6781 (23°C/50%RH) test speed: 50 mm/min. |

| Yield strength | MD* TD* | N/mm2 | - | 80 75 |

|

| Tensile strength | MD* TD* | N/mm2 | 81 84 | 135 83 |

|

| Elongation | MD* TD* | % | 223 235 | 72 239 |

|

| Breakdown voltage | kV/mm | 22.6 | JIS C2110 Elec cylinder: (23°C/50%RH) |

||

| Dielectric strength | kV/mm | - | 16 | ||

| Dielectric constant | - | - | 3.30 | ||

| Dielectric tangential loss | - | - | 0.003 (1 GHz) | ||

| Thermal conductivity | W/m•K | 0.25 | |||

| Flame retardance (UL94) | - | - | V-0 (1.5 mm) | ||

| Water absorbing property (23°C / 24 hrs) | - | - | 0.1 | ||

| Density | kg/dm3 | 1.32 | |||

| Gas permeability | O2 N2 CO2 | cc(stp)/m2 | 3.0 • 10^3 7.5 • 10^1 5.9 • 10^3 | JIS K7126-1 (Diff pressure method) (24 hrs @ atm) |

|

| * MD is machining direction / TD is transverse direction. | |||||

PEEK - extended material property at 120 ºC

| Unit | T = 3 µm | T = 7 µm | ||

|---|---|---|---|---|

| Tensile strength | MD* TD* | N/mm2 | 69 59 | 67 45 |

| Tensile strain at break | MD* TD* | % | 107 243 | 94 192 |

| Modulus of elasticity in tension (Young) | MD* TD* | N/mm2 | 1980 1380 | 1970 1550 |

| Degree of crystallization | % | < 10 | 20 ~ 30 | |

| * MD is machining direction / TD is transverse direction Test method: JIS K7160-3 (120°C), tensile speed: 50 mm/min. |

||||

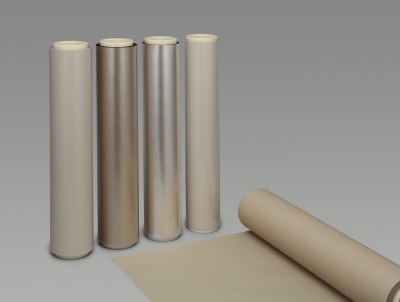

PEEK film dimensions and tolerances

| Unit | Value | ||

|---|---|---|---|

| Thickness of film | T | µm | 3 ~ 50 ± 5% * 6 ~ 250 ± 5% ** |

| Width of film (on roll) | W | mm | 650 or 1310 |

| Length of film on roll (max) | L | m | 2000 (3~6 µm T) 1000 (7~20 µm T) 750 (21~25 µm T) 300 (26~50 µm T) |

| Core of roll | ∅ | inch | 3 or 6 |

| * Non-stretched film of amorphous plastics ** Non-stretched and high crystallized film of crystallized plastics The average value complaint with JIS C2330:2010 and IEC60674-3-1:1998 (n5*20) |

|||