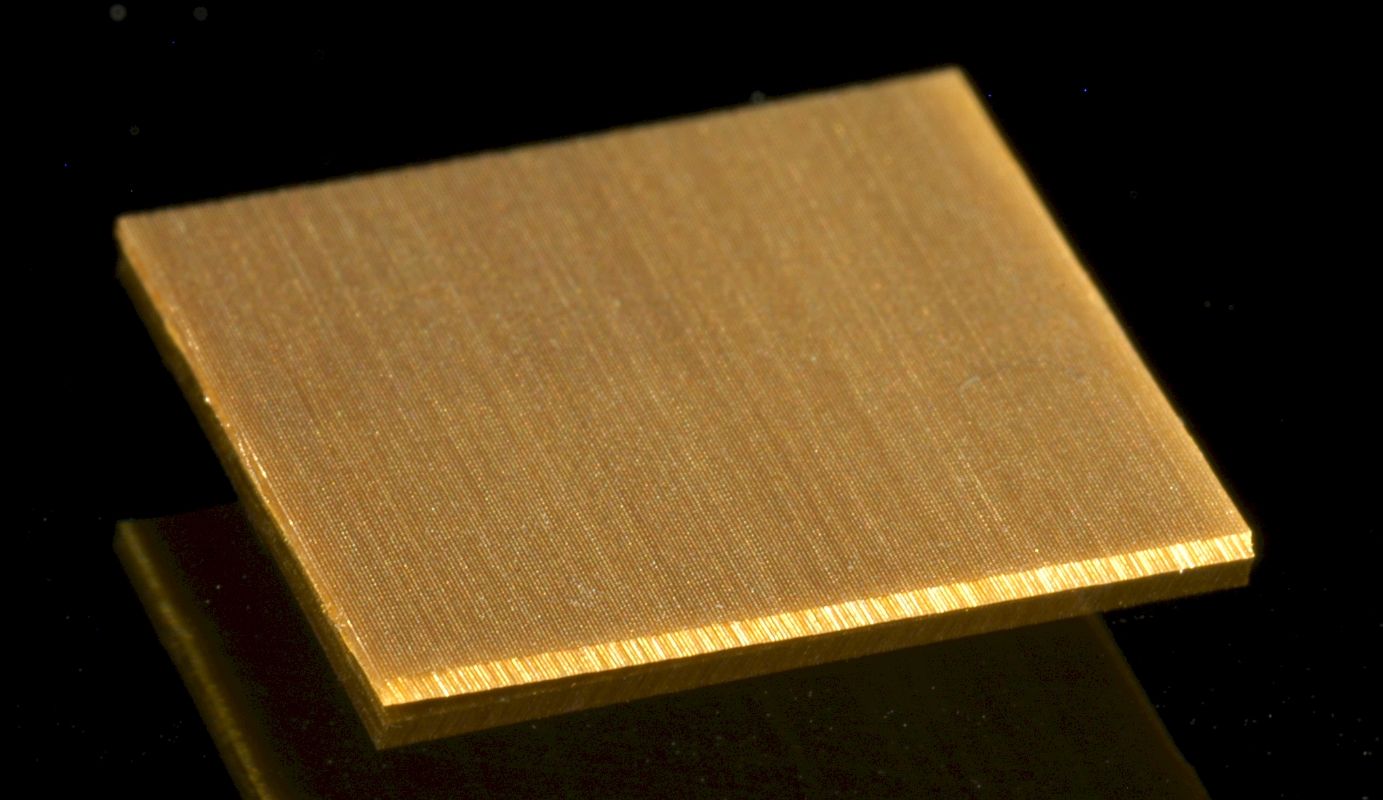

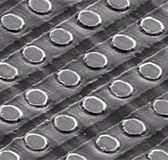

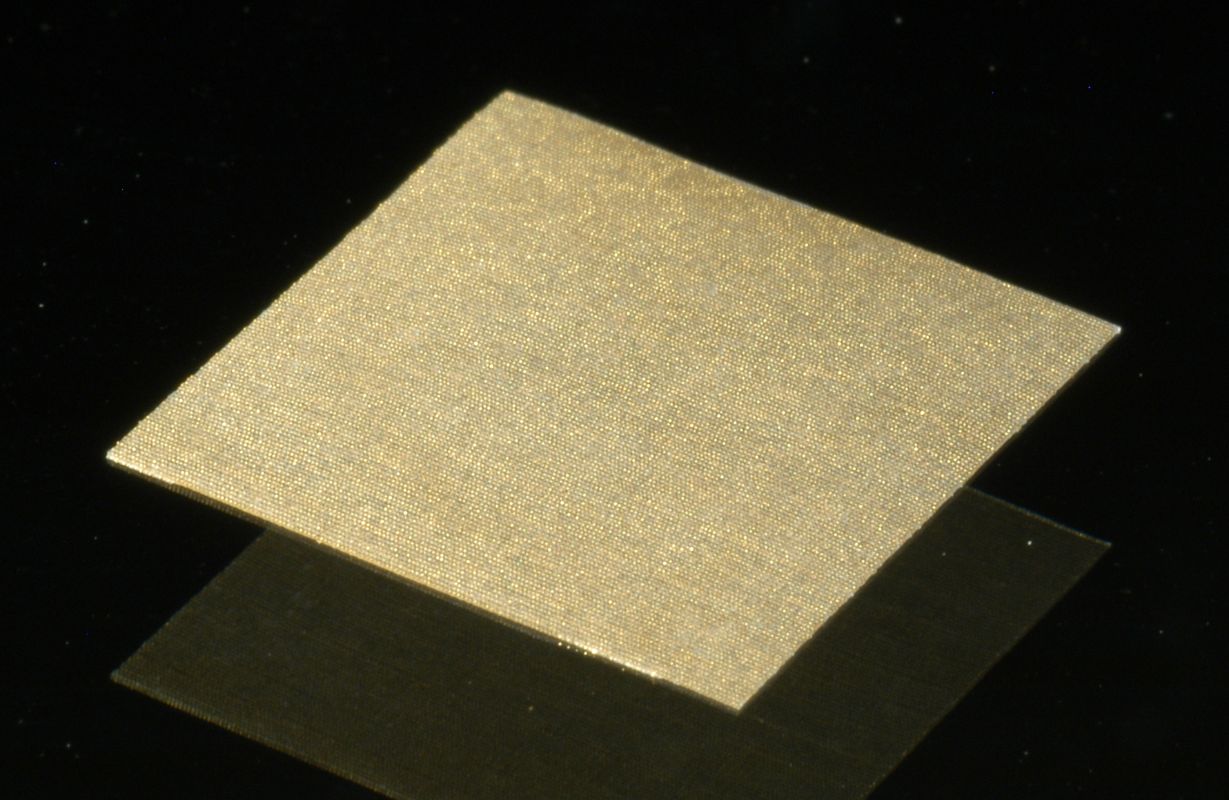

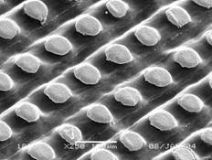

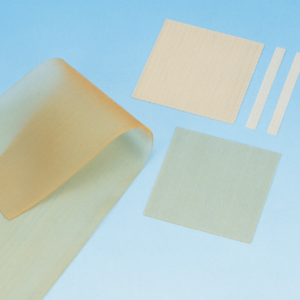

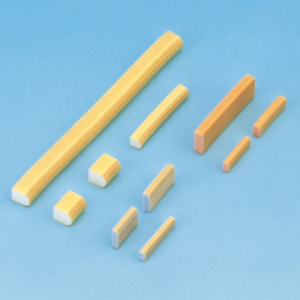

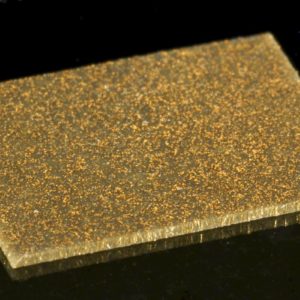

The MT-type of Inter-Connector, used for testing IC-devices in packages like BGA, QFP, SOP, Flip-Chip or Bumped Wafers, consists of parallel rows of gold-plated brass wires in a silicone rubber sheet.

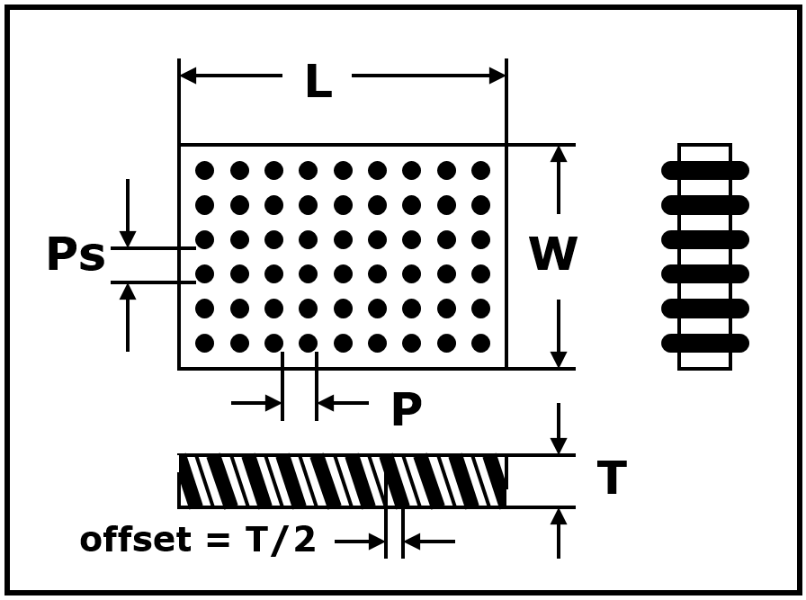

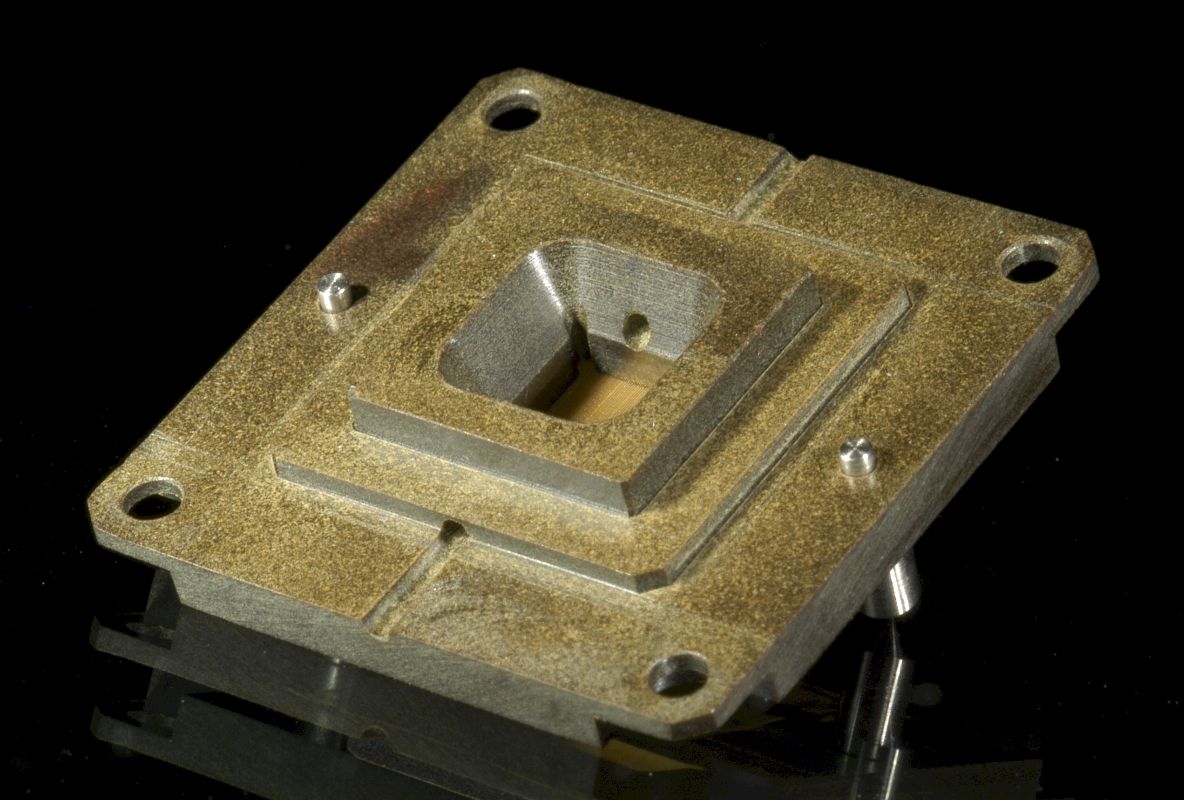

Wires are positioned under an angle of 60° to ease compression and improve durability. The wire angle of 60° requires contacts to use an offset of half the thickness of the silicone rubber sheet. Randomly positioning the Inter-Connector between contact pads and providing compresssion wil realize a stable, low resistance connection.

Proper connection is provided by compression forces of 0.2 ~ 0.5 N per contact ball or land on the IC device, depending on the contact size and shape.

The MT-type is one of the derivatives of the GB-type and the base of several versions of MT-types dedicated to specialized fields of device testing. The MT-4X is having a 4 times higher wire density for fine pitch IC devices. The MT-T is providing ultra high signal transmission up to 13 Ghz due to its small sheet thickness.

The MT-P is having wires protruding the sheet surface by 20 µm to ease contacting ultra fine and mechanically sensitive devices with flat contacts like LGA packages. The protruded wires of the MT-P-type are Ni/Au-plated.

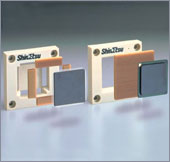

MT Type Dimensions

Full data in download| Parameter | Unit | Value |

|---|---|---|

| Pitch P, Ps | mm | 0.05/ 0.1 |

| Sheet thickness | mm | 0.1 ~ 2 |

| Length | mm | 5 ~ 50 |

| Width | mm | 5 ~ 50 |

| Conductive fiber diameter | µm | 23/ 40 |

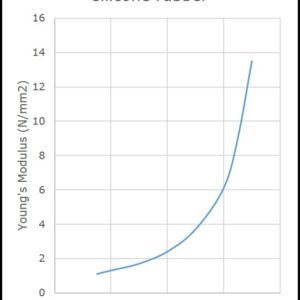

MT Type Properties

Full data in download| Parameter | Unit | Value |

|---|---|---|

| Contact resistance | Ω | < 0.1 |

| Current carrying capacity | mA/wire | 50 |

| Dielectric breakdown voltage | kV/mm | 23 ~ 27 |

| Isolation resistance (500V DC) *** | MΩ | > 10^3 |

| Operating temperature range | °C | -35 ~ 100 |