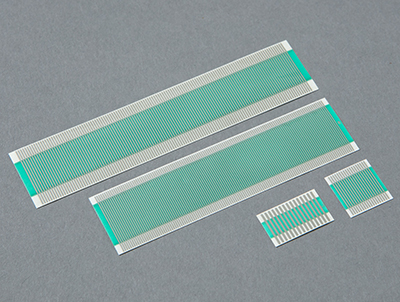

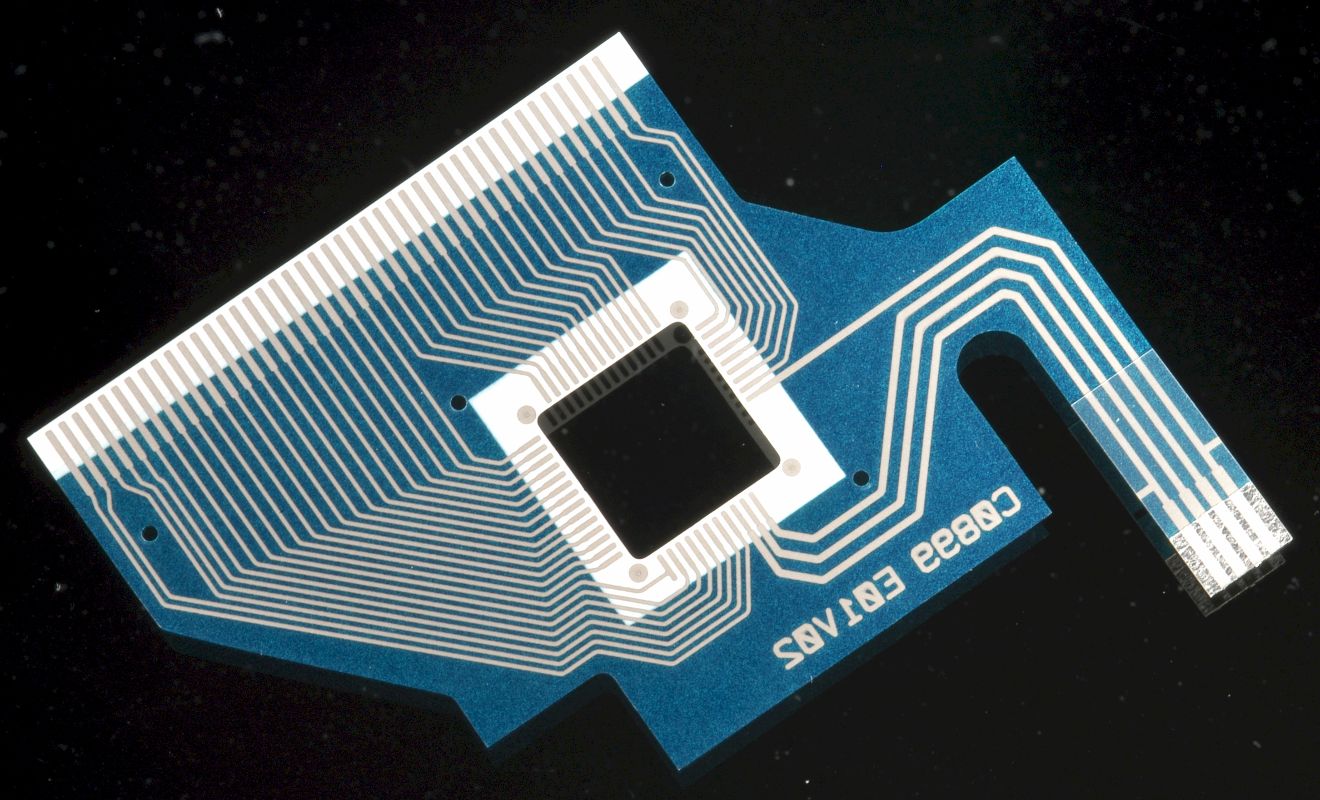

The JS-type of Inter-Connector, used for LCD’s that require lower resistance or fine pitches, is a PET film substrate with printed silver tracks. The Inter-Connector has to be heatsealed to the LCD and PCB with the applied anisotropic adhesive that covers the silver tracks at the bonding area. JS-type of Inter-Connectors are designed to custom requirements and need custom tooling.

Special bonding equipment is required. Two system are in use at customers, based on constant heaters and pulse heaters as used in hotbar solder reflow machines. Assistance can be given to select equipment suppliers.

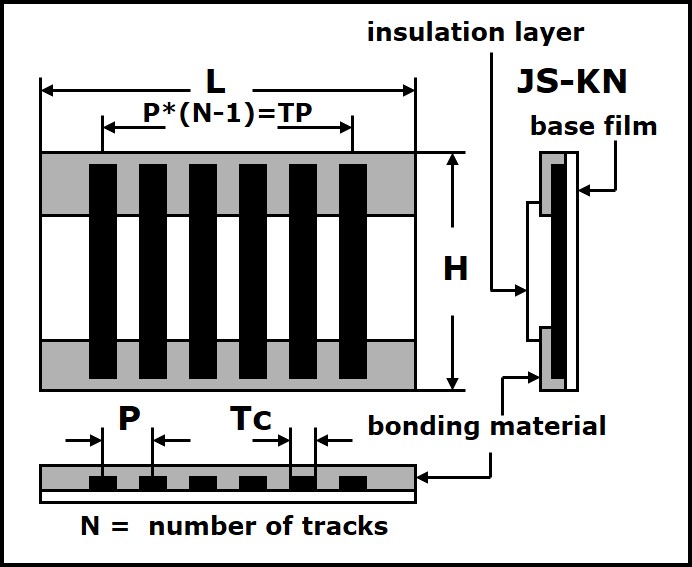

JS Type Dimensions

| Parameter | Unit | Value |

| Pitch | mm | ≥ 0.19 |

| Length | mm | ≤ 100 |

| Height | mm | 10 ~ 150 |

| Width conductive track | mm | ≥ 0.1 |

| Thickness of base film | µm | 25 |

| Thickness of cover film (optional) | µm | 12/ 25 |

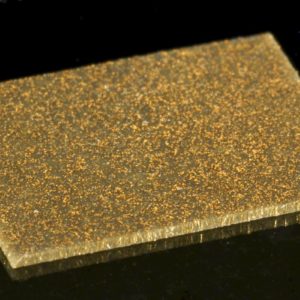

JS Type construction

| Part | Material |

| Base film | PET |

| Conductive lines | Thermosetting resin silver/carbon ink |

| Adhesive | Semi-thermosetting synthetic rubber |

| Conductive particles in adhesive | Gold-plated carbon particles |

| Isolation layer | Printed thermoplastic synthetic rubber |

| Cover film (optional) | PET |

JS Type property and bonding condition

| Parameter | Unit | Value |

| Surface resistance conductive line | Ω/sq | < 0.5 |

| Isolation resistance | MΩ | ≥ 100 |

| Peel strength | N/cm | ≥ 3 |

| Operating temperature range | °C | -40 ~ 85 |

| Bonding adhesive temperature | °C | 140 ~ 170 |

| Bonding pressure | MPa | 3.5 |

| Bonding time | s | 7 |