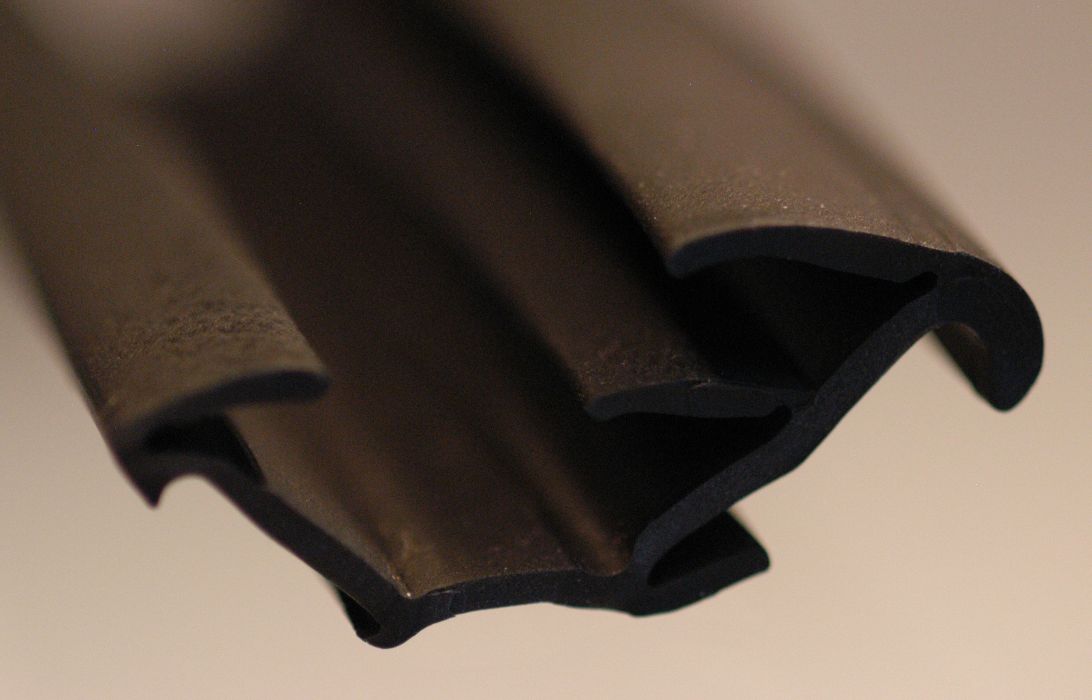

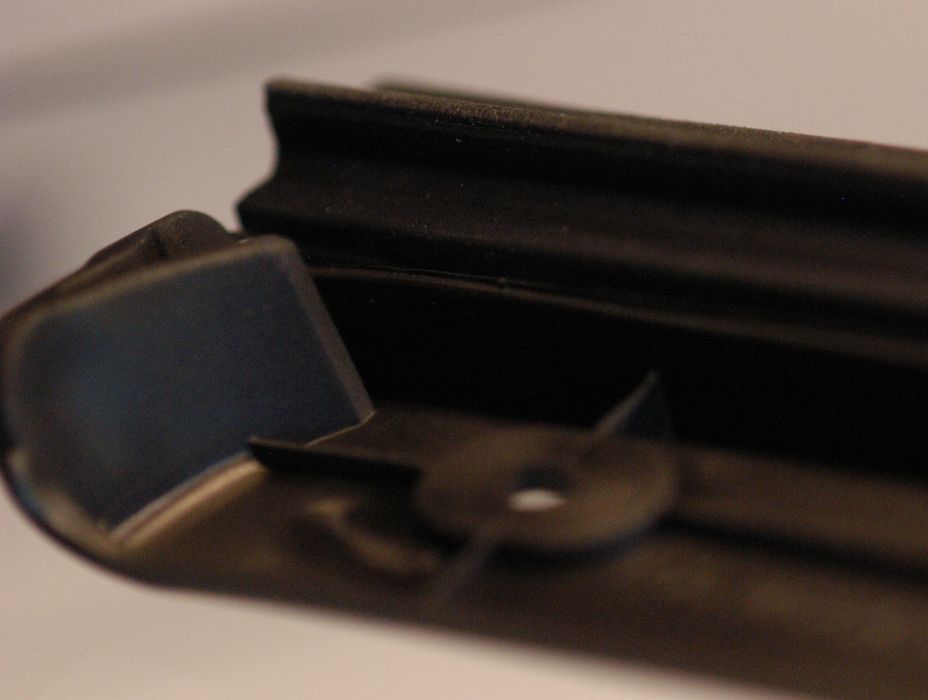

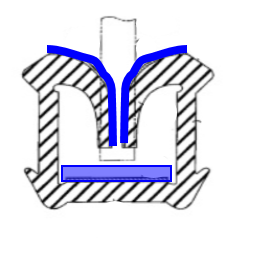

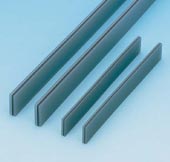

SX-500 series is a silicone and olefin thermoplastic moulding material for extruding automotive door profiles or construction sash window seals. SX500 olefin’s thermoplastic elastomer to reducing the sliding resistance and prevent squeak noise of glass panels touching the profiles.

Trend in production of automotive sealing parts is material recycling and reduction of energy usage. EPDM profiles can be redesigned into TPU profiles. Extended curing lines for EPDM can be replaced by small extrusion machines. Complicated Flock production can be replaced by additing Exelast as slip coat on automotive door sealing profiles.

Features:

- co-extruding from 50 µm layer slipcoat on TPU or EPDM automotive door profiles

- maintain long term low friction resistance

- perform excellent elasticity and durability

- suppress squeak noise when repeated sliding of glass window panels

- cost effective and durable replacement of flock

- excellent abrasion resistance

- good appearance due to less bending marks on a variety of shapes

Exelast SX-500 properties

| Parameter | Unit | Value |

|---|---|---|

| Color | -- | Black |

| Hardness (Shore D) | -- | 49/ 48 |

| Melt flow index 230ºC/5 kg | g/10min | 15/ 9 |

| Tensile strength | MPa | 13.6/ 13.7 |

| Elongation | % | 183/ 188 |

| Tear strength | N/cm | 53.8/ 62.6 |

| Static coefficient of friction | -- | 0.24/ 0.26 |

| Dynamic coefficient of friction | -- | 0.11/ 0.13 |